© Cotton Technology International

STARFISH Software

Build Your Own Cotton Knitted Fabric Engineering Software

1 . General Outline 2 . How it works 3 . Introduction & Overview 4 . Code segmentsGeneral Outline

STARFISH is short for "START as you mean to FINISH". It is a computer program, and a body of know-how, which can demonstrate how to engineer cotton circular knits so that the quality and the performance can be right first time and on time. The STARFISH computer program is a simulator. It models the key elements of production and processing of cotton circular knitted fabrics and it calculates their expected performance. When they have to develop a new product with defined levels of weight, width, and shrinkage most companies start with educated guesswork, proceed to trial and error knitting and finishing trials, and finish with a product which may or may not be close to the target after a few attempts. With STARFISH a development trial can be simulated on the computer in five minutes. If it does not produce the right performance, a dozen further trials can be simulated in another five minutes. If the specified performance is physically possible, using the available materials and machinery, STARFISH will show how to do it inside an hour with no charge for materials or processing. If the required performance is not physically possible, using the available materials and machinery, STARFISH will show what alternatives are possible, what compromises will have to be made, or what additional resources will need to be acquired. The STARFISH computer program tells you how to engineer your products for a given performance and presents you with manufacturing targets. The STARFISH know-how shows you how to meet the targets and how to maintain them consistently. The STARFISH computer program has been developed from the results of a twenty- four year research and development project during which more than five thousand different qualities of knitted fabrics were manufactured and processed, using full- scale commercial equipment, together with cross-checking of routine production in the industry. Industrial checks have shown that, provided the fabric and processing are correctly specified (and especially after local calibration) the predictions provided by STARFISH are usually within one standard deviation of the average measured values obtained from comparable fabrics in routine production. There are currently more than 264 STARFISH licensees in 52 countries. Several STARFISH users have commented that the cost of the program was recovered the first time it was used. Starfish has now been withdrawn from the market and is no longer available for purchase, because its authors no longer have the personal and financial resources to keep it up to date. This section is provided so that any interested and competent software programmers, can develop a modern version. Since CTI itself is no longer able to continue the development of Starfish, we are placing the background information here on this website so that, in principle, others can take up the challenge - or utilise (some of) the data for PhD studies. We are not listing all of the actual source code because it is in an obsolete programming language (Visual Basic 6.0 / Jet 3.5 / WinHelp). However, some key sections of code, especially the Starfish Engine are given below. If you need more information, get in touch . If you use the information on this website to construct some new knitted fabric engineering software, or to provide data for a PhD study, or whatever, we hope that you will acknowledge the origin of your source material. We would also appreciate your letting us know - you never know, we might be able to help. Back to Top

How it works

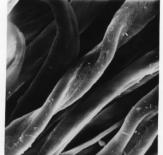

The description below outlines the foundation upon which the program is built, and which will have to be included (or improved) in any modern version. The rest of the program, as with most software, is simply the outer shell - the user interface - which is a matter of taste and can be erected according to local requirements. At the heart of the program is the Starfish Engine . This is where all of the calculations are made that turn the inputs into predictions. The code resides in a module called Engine.Bas and the key subroutine is Public Sub GetDataSet (Inputs() As Single, EngineErr as Boolean). GetDataSet is called whenever the user changes any value or measurement unit or manufacturing environment option that would affect the dimensional properties of the selected fabric quality. The properties of the selected fabric quality are held in a Public array called P(), with 55 members. The specification for this and most other important variables is to be found in a module called Comments.Bas. For example, item P(1) contains the value for the yarn count, as knitted, in tex units (the Starfish Default Unit for yarn count), whereas item P(23) contains the value for the yarn count, as knitted, in User Units (the units of measurement specified by the user). The change that would be caused by the change in Manufacturing System , Working Environment , or Quality Values requested by the user is calculated and the data in the P() array are updated accordingly. The calculation proceeds in five steps. 1 . The inputs, which are always in User Units , are assigned to the appropriate positions in P() . The corresponding values are calculated in Default Units and placed at the appropriate positions in P() . 2 . The Reference State yarn count and stitch length are calculated using the Starfish Step 1 Equations (see below) and assigned to P(). 3 . The Reference State fabric dimensional properties are calculated using the Starfish Step 2 Equations and assigned to P() . Results are in Starfish Default Units . 4 . The As-delivered fabric dimensional properties are calculated using the Standard Equations and assigned to P() . Results are in Starfish Default Units . 5 . The As-delivered properties are converted to the corresponding values in User Units and assigned to P() . The Equations Actually, there are two sets of equations, the Reference Equations and the Standard Equations . The Standard Equations are those that are (or should be) well known and are taught in all good textile colleges. The key equations are as follows. 1 ) Length Shrinkage (%) = 100 (Lo - Lr) / Lo 2 ) Width Shrinkage (%) = 100 (Xo - Xr) / Xo 3 ) Length Shrinkage (%) = 100 (Cr - Co) / Cr 4 ) Width Shrinkage (%) = 100 (Wr - Wo) / Wr 5 ) Open Width (cm) = Needles / Wales per cm 6 ) Weight (gsm) = Courses/cm . Wales/cm . Yarn count (tex) . Stitch length (cm) . F where: Lo is the original length of the test piece (before the relaxation process); Lr is the relaxed length of the test piece (after the relaxation process); Xo is the original width of the test piece (before the relaxation process); Xr is the relaxed width of the test piece (after the relaxation process); Co is the course density of the original test piece; Cr is the course density of the relaxed test piece; Wo is the wale density of the original test piece; Wr is the wale density of the relaxed test piece; F is a factor whose value depends on the fabric type and how the course and wale densities are expressed (visible stitches, true stitches, cells). The Reference Equations are those that have been discovered by the Starfish Research Project. So far as we know, they are unique to Starfish. They represent the current state of our knowledge but it has to be said that our knowledge is imperfect. It is quite likely that other workers could (and may yet) develop a better set of equations which could be more accurate and/or more comprehensive. In developing the Reference Equations , we start from four basic ideas. 1 . The equations that we require are those that link the manufacturing variables (fabric type, yarn type and twist density, yarn count, knitting machine and knitted course length, type and severity of wet processing, and depth of shade in dyeing) to the properties of the final dyed and finished fabric. In particular, we need to be able to predict the course and wale densities , since these are the major unknowns that appear in the right-hand sides of the Standard Equations . 2 . The variables contained in the equations should be only those that can easily be measured in a good industrial testing laboratory. For example, it is very likely that yarn properties such as diameter, stiffness and residual torque (twist liveliness) influence the course and wale densities but these can not easily be measured, so we have to make do with proxy properties such as yarn type, count and twist. 3 . It follows that the required equation coefficients have to be determined empirically, (i.e. by extensive industrial trials) for at least three reasons. a . As mentioned in 2, parameters such as yarn stiffness and torque are not susceptible to convenient measurement in an industrial textile laboratory. b . Even if it were convenient to measure these difficult properties, there is actually no theoretical basis, at present, for constructing the required equations from these parameters. c . Even if it were possible to construct theoretical equations linking the basic fibre and yarn properties to the course and wale densities of (grey) knitted fabric, the inconvenient fact is that wet processing treatments alter these fibre and yarn properties in a way that is not precisely predictable (nor even measurable). 4 . In order to have equations of maximum reliability, they have to describe the dimensions of the fabric in its Fully Relaxed state. This is because any other state of relaxation is unreliable, in the sense that the dimensions are capable of further change as a result of additional relaxation. Back to Top Extensive research shows that: • The Fully Relaxed State may require up to about 10 cycles of laundering (in a domestic automatic washing machine, with standard detergent at 60 deg Celsius followed by tumble drying) depending on the fabric type and the wet processing it has received. Even for research studies this is a very expensive and time-consuming relaxation process. • After five cycles of washing and tumble drying, most fabrics achieve a state of relaxation that is pretty close to the Fully Relaxed State and is pretty reproducible. • After the first cycle, the washing at 60 deg Celsius can be replaced by a short wet out, rinse and spin without loss in reliability. • After each cycle, tumble drying should continue until the test pieces are all uniformly dry (less than about 3% moisture content), followed by conditioning (ideally in the standard atmosphere) before measuring. • Inclusion of fabric softener in the rinse alters the results and makes them somewhat less reliable. Therefore, the Starfish Reference Relaxation Procedure has been defined as: 1 . One full cycle washing at 60 Celsius with standard detergent, no softener, tumble dry to less than 3% moisture content, followed by 2 . Four cycles rinse, spin and tumble dry to < 3% moisture content. 3 . Condition at 20 Celsius and 65% RH for at least four hours and preferably overnight. Fabrics that have been subjected to the Starfish Reference Relaxation Procedure are said to be in their Reference State of Relaxation . All of the test samples of the Starfish Research Project have had their properties measured in the Reference State and the Starfish Reference Equations refer to fabrics in the Reference State . During the Starfish Research Project, thousands of fabric samples have been measured and the test data analysed. Due to the incremental and evolutionary nature of the project, the form and detail of the resulting equations has changed several times - and no doubt will change again in the future. The current (2019) Starfish Equations have the following basic form. Step 1 : Calculate the Reference tex and stitch length Reference tex, T = TexRat . As-knitted tex Reference stitch length, L = SLRat . As-knitted stitch length Step 2 : Calculate Reference Course & Wale Densities Reference Courses/cm, Cr = Sc / L - Fc . T P Reference Wales/cm, Wr = Sw / L + Fw . T Q In the Step 1 equations, TexRat and SLRat are empirically determined constants for a given yarn type and wet process. They seem to be the same for all (cotton) fabric types and have been found from the average slope of large numbers of plots that show the effect of the wet processing upon the values of tex and stitch length. There are three main influences: yarn shrinkage; removal of impurities; addition of dyes and chemicals. More detail is given in the Starfish Training Course and the Starfish Help . Reports on basic research studies are given in the STARFISH Archive . In the Step 2 equations, Sc and Sw are empirically determined constants for a given fabric type; Fc and Fw are empirically determined constants for a given fabric type, yarn type and wet process. The Step 2 exponents of Tex, P and Q , are also empirically determined and seem to take the same value for all (cotton) fabric types. They have been arrived at as follows. For each fabric - yarn tex combination, a plot is made of Reference Courses or Wales per cm versus the reciprocal of the stitch length. For a large number of such plots the average slope, Sc or Sw is determined for each fabric type. Using Sc or Sw, the average intercept of the line is calculated for each yarn tex value. These intercepts, Ic and Iw , are plotted as a function of the yarn tex, and a power-law curve is fitted by regression analysis. Thus: Ic = Fc . tex P and Iw = Fw . tex Q The average exponent of the power law functions, for the different fabric types is calculated and is found to be approximately P = -0.7 for the Courses, and Q = -0.6 for the Wales, independent of the fabric type. Note: In the scientific and technical literature, there are many studies that show the dependence of the Course and Wale densities upon the reciprocal of Stitch Length. Some of these studies derive constants analogous to Sc and Sw (often termed K factors). A few derive constants equivalent to Ic and Iw . However, all of these studies have at least one of the following limitations: a . They are carried out on small, laboratory samples: no industrial-scale processing is involved. b . They are carried out on grey fabrics only. The constants for grey fabrics are of no value in predicting the properties of dyed and finished fabrics. c . The measurements are not made on Fully Relaxed, or Reference State samples, so the reported values are unreliable. d . The scope of the project is too narrow. It is in the very nature of such experiments that the measured values of Course and Wale densities, and hence the derived constants, are rather variable. This is mainly for two reasons. i . Most laboratory technicians and undergraduate students in industrial or academic laboratories (however capable or conscientious) are not sufficiently experienced or not sufficiently well-trained to be able to deliver consistent test data. i i . The Fully Relaxed State (which the Starfish Reference State approximates) is supposed to represent a condition of zero internal energy in the fabric: when all internal restraints have been removed and the fabric is incapable of further relaxation. This condition is rather difficult to achieve and is only ever approximated. Therefore, in order to have reliable values for the equation constants, it is necessary to carry out a large number of tests on a wide range of fabrics, processed through a wide range of (industrial-scale) wet processing routes. This requirement is almost never met in studies that appear in the literature. The Starfish Database contains measurements on thousands of samples but, if even larger amounts of data were available, it is quite likely that the constants, Sc , Sw , Fc , Fw , P & Q could be re-calculated to be slightly different. It should be noted that some fabric types, yarn types, and wet processing routes are represented to a much greater extent (and with a much wider range of yarn tex values) than others in the Starfish Database . If all fabric, yarn, and processing types were equally represented, it might be possible to distinguish more precisely the effects of these major variables upon the coefficients of the Starfish Reference Equations . The exponents, P & Q , are encapsulating the influences of all of the separate (and difficult-to-measure) yarn properties that are dependent on the yarn tex value, such as diameter, stiffness, and twist liveliness (torque). These influences are generally thought to be related to the square root of the tex value, so the exponent was expected to be -0.5. However, there is also expected to be an influence of the fibre fineness which may partly explain why -0.5 turned out not to give the best fit. It is the Fc and Fw coefficients that are used by the calibration routines in STARFISH to tailor the output of the model for a given set of processing conditions. This fact can be exploited, without need for the Starfish software. For example, any manufacturing company is in possession of large amounts of routine quality control data. These data are often just filed away and forgotten, but they can be used to form simple predictive equations that can be used during product development. This is done by, effectively, discovering the Ic and Iw values for the particular circumstances. The current values of all of these equation coefficients are given in the Program Code Segments given below. Back to TopSoftware Introduction & Overview

On the Starfish Install CD there is a set of PowerPoint presentations which give a brief introduction to the Starfish Research Project and the Starfish Technology. These presentations could be very useful to anyone who wishes to construct a modern piece of software in as much as they give a good representation of the on-screen appearance of the software, thus indicating all of the information that has to be presented to the user. The three that refer to the software are available here. Obviously, Microsoft’s PowerPoint Viewer will have to be downloaded to be able to run the presentations. 1 . Introduction 2 . Get Started 3 . Special Features In addition, scattered about the Program Help are bits of descriptive text which illustrate how Starfish is constructed and how it operates. These have been collected into seven documents, which are given here. 1 . Basic Technological Concepts 2 . Fabric Types 3 . Fabric Properties 4 . Knitting Parameters 5 . Knitting Production Parameters 6 . Wet Processing Parameters 7 . Definition of a STARFISH modelProgram Code Segments

These program snippets are lifted from STARFISH Version 6.5. Among the Research Records , you can find descriptions of earlier versions of the program, which may give some insight into the way that STARFISH evolved: from a calculation aid, to an in-house prediction utility, to a piece of commercial software. 1 . The STARFISH Engine 2 . Initialisation of variables - Including Reference State Equation Coefficients 3 . Comments - contents of major variables Back to Top .

How it works

The description below outlines the foundation upon which the program is built, and which will have to be included (or improved) in any modern version. The rest of the program, as with most software, is simply the outer shell - the user interface - which is a matter of taste and can be erected according to local requirements. At the heart of the program is the Starfish Engine . This is where all of the calculations are made that turn the inputs into predictions. The code resides in a module called Engine.Bas and the key subroutine is Public Sub GetDataSet (Inputs() As Single, EngineErr as Boolean). GetDataSet is called whenever the user changes any value or measurement unit or manufacturing environment option that would affect the dimensional properties of the selected fabric quality. The properties of the selected fabric quality are held in a Public array called P(), with 55 members. The specification for this and most other important variables is to be found in a module called Comments.Bas. For example, item P(1) contains the value for the yarn count, as knitted, in tex units (the Starfish Default Unit for yarn count), whereas item P(23) contains the value for the yarn count, as knitted, in User Units (the units of measurement specified by the user). The change that would be caused by the change in Manufacturing System , Working Environment , or Quality Values requested by the user is calculated and the data in the P() array are updated accordingly. The calculation proceeds in five steps. 1 . The inputs, which are always in User Units , are assigned to the appropriate positions in P() . The corresponding values are calculated in Default Units and placed at the appropriate positions in P() . 2 . The Reference State yarn count and stitch length are calculated using the Starfish Step 1 Equations (see below) and assigned to P(). 3 . The Reference State fabric dimensional properties are calculated using the Starfish Step 2 Equations and assigned to P() . Results are in Starfish Default Units . 4 . The As-delivered fabric dimensional properties are calculated using the Standard Equations and assigned to P() . Results are in Starfish Default Units . 5 . The As-delivered properties are converted to the corresponding values in User Units and assigned to P() . The Equations Actually, there are two sets of equations, the Reference Equations and the Standard Equations . The Standard Equations are those that are (or should be) well known and are taught in all good textile colleges. The key equations are as follows. 1 ) Length Shrinkage (%) = 100 (Lo - Lr) / Lo 2 ) Width Shrinkage (%) = 100 (Xo - Xr) / Xo 3 ) Length Shrinkage (%) = 100 (Cr - Co) / Cr 4 ) Width Shrinkage (%) = 100 (Wr - Wo) / Wr 5 ) Open Width (cm) = Needles / Wales per cm 6 ) Weight (gsm) = Courses/cm . Wales/cm . Yarn count (tex) . Stitch length (cm) . F where: Lo is the original length of the test piece (before the relaxation process); Lr is the relaxed length of the test piece (after the relaxation process); Xo is the original width of the test piece (before the relaxation process); Xr is the relaxed width of the test piece (after the relaxation process); Co is the course density of the original test piece; Cr is the course density of the relaxed test piece; Wo is the wale density of the original test piece; Wr is the wale density of the relaxed test piece; F is a factor whose value depends on the fabric type and how the course and wale densities are expressed (visible stitches, true stitches, cells). The Reference Equations are those that have been discovered by the Starfish Research Project. So far as we know, they are unique to Starfish. They represent the current state of our knowledge but it has to be said that our knowledge is imperfect. It is quite likely that other workers could (and may yet) develop a better set of equations which could be more accurate and/or more comprehensive. In developing the Reference Equations , we start from four basic ideas. 1 . The equations that we require are those that link the manufacturing variables (fabric type, yarn type and twist density, yarn count, knitting machine and knitted course length, type and severity of wet processing, and depth of shade in dyeing) to the properties of the final dyed and finished fabric. In particular, we need to be able to predict the course and wale densities , since these are the major unknowns that appear in the right-hand sides of the Standard Equations . 2 . The variables contained in the equations should be only those that can easily be measured in a good industrial testing laboratory. For example, it is very likely that yarn properties such as diameter, stiffness and residual torque (twist liveliness) influence the course and wale densities but these can not easily be measured, so we have to make do with proxy properties such as yarn type, count and twist. 3 . It follows that the required equation coefficients have to be determined empirically, (i.e. by extensive industrial trials) for at least three reasons. a . As mentioned in 2, parameters such as yarn stiffness and torque are not susceptible to convenient measurement in an industrial textile laboratory. b . Even if it were convenient to measure these difficult properties, there is actually no theoretical basis, at present, for constructing the required equations from these parameters. c . Even if it were possible to construct theoretical equations linking the basic fibre and yarn properties to the course and wale densities of (grey) knitted fabric, the inconvenient fact is that wet processing treatments alter these fibre and yarn properties in a way that is not precisely predictable (nor even measurable). 4 . In order to have equations of maximum reliability, they have to describe the dimensions of the fabric in its Fully Relaxed state. This is because any other state of relaxation is unreliable, in the sense that the dimensions are capable of further change as a result of additional relaxation. Back to Top Extensive research shows that: • The Fully Relaxed State may require up to about 10 cycles of laundering (in a domestic automatic washing machine, with standard detergent at 60 deg Celsius followed by tumble drying) depending on the fabric type and the wet processing it has received. Even for research studies this is a very expensive and time-consuming relaxation process. • After five cycles of washing and tumble drying, most fabrics achieve a state of relaxation that is pretty close to the Fully Relaxed State and is pretty reproducible. • After the first cycle, the washing at 60 deg Celsius can be replaced by a short wet out, rinse and spin without loss in reliability. • After each cycle, tumble drying should continue until the test pieces are all uniformly dry (less than about 3% moisture content), followed by conditioning (ideally in the standard atmosphere) before measuring. • Inclusion of fabric softener in the rinse alters the results and makes them somewhat less reliable. Therefore, the Starfish Reference Relaxation Procedure has been defined as: 1 . One full cycle washing at 60 Celsius with standard detergent, no softener, tumble dry to less than 3% moisture content, followed by 2 . Four cycles rinse, spin and tumble dry to < 3% moisture content. 3 . Condition at 20 Celsius and 65% RH for at least four hours and preferably overnight. Fabrics that have been subjected to the Starfish Reference Relaxation Procedure are said to be in their Reference State of Relaxation . All of the test samples of the Starfish Research Project have had their properties measured in the Reference State and the Starfish Reference Equations refer to fabrics in the Reference State . During the Starfish Research Project, thousands of fabric samples have been measured and the test data analysed. Due to the incremental and evolutionary nature of the project, the form and detail of the resulting equations has changed several times - and no doubt will change again in the future. The current (2019) Starfish Equations have the following basic form. Step 1 : Calculate the Reference tex and stitch length Reference tex, T = TexRat . As-knitted tex Reference stitch length, L = SLRat . As-knitted stitch length Step 2 : Calculate Reference Course & Wale Densities Reference Courses/cm, Cr = Sc / L - Fc . T P Reference Wales/cm, Wr = Sw / L + Fw . T Q In the Step 1 equations, TexRat and SLRat are empirically determined constants for a given yarn type and wet process. They seem to be the same for all (cotton) fabric types and have been found from the average slope of large numbers of plots that show the effect of the wet processing upon the values of tex and stitch length. There are three main influences: yarn shrinkage; removal of impurities; addition of dyes and chemicals. More detail is given in the Starfish Training Course and the Starfish Help . Reports on basic research studies are given in the STARFISH Archive . In the Step 2 equations, Sc and Sw are empirically determined constants for a given fabric type; Fc and Fw are empirically determined constants for a given fabric type, yarn type and wet process. The Step 2 exponents of Tex, P and Q , are also empirically determined and seem to take the same value for all (cotton) fabric types. They have been arrived at as follows. For each fabric - yarn tex combination, a plot is made of Reference Courses or Wales per cm versus the reciprocal of the stitch length. For a large number of such plots the average slope, Sc or Sw is determined for each fabric type. Using Sc or Sw, the average intercept of the line is calculated for each yarn tex value. These intercepts, Ic and Iw , are plotted as a function of the yarn tex, and a power-law curve is fitted by regression analysis. Thus: Ic = Fc . tex P and Iw = Fw . tex Q The average exponent of the power law functions, for the different fabric types is calculated and is found to be approximately P = -0.7 for the Courses, and Q = -0.6 for the Wales, independent of the fabric type. Note: In the scientific and technical literature, there are many studies that show the dependence of the Course and Wale densities upon the reciprocal of Stitch Length. Some of these studies derive constants analogous to Sc and Sw (often termed K factors). A few derive constants equivalent to Ic and Iw . However, all of these studies have at least one of the following limitations: a . They are carried out on small, laboratory samples: no industrial-scale processing is involved. b . They are carried out on grey fabrics only. The constants for grey fabrics are of no value in predicting the properties of dyed and finished fabrics. c . The measurements are not made on Fully Relaxed, or Reference State samples, so the reported values are unreliable. d . The scope of the project is too narrow. It is in the very nature of such experiments that the measured values of Course and Wale densities, and hence the derived constants, are rather variable. This is mainly for two reasons. i . Most laboratory technicians and undergraduate students in industrial or academic laboratories (however capable or conscientious) are not sufficiently experienced or not sufficiently well- trained to be able to deliver consistent test data. i i . The Fully Relaxed State (which the Starfish Reference State approximates) is supposed to represent a condition of zero internal energy in the fabric: when all internal restraints have been removed and the fabric is incapable of further relaxation. This condition is rather difficult to achieve and is only ever approximated. Therefore, in order to have reliable values for the equation constants, it is necessary to carry out a large number of tests on a wide range of fabrics, processed through a wide range of (industrial-scale) wet processing routes. This requirement is almost never met in studies that appear in the literature. The Starfish Database contains measurements on thousands of samples but, if even larger amounts of data were available, it is quite likely that the constants, Sc , Sw , Fc , Fw , P & Q could be re-calculated to be slightly different. It should be noted that some fabric types, yarn types, and wet processing routes are represented to a much greater extent (and with a much wider range of yarn tex values) than others in the Starfish Database . If all fabric, yarn, and processing types were equally represented, it might be possible to distinguish more precisely the effects of these major variables upon the coefficients of the Starfish Reference Equations . The exponents, P & Q , are encapsulating the influences of all of the separate (and difficult-to-measure) yarn properties that are dependent on the yarn tex value, such as diameter, stiffness, and twist liveliness (torque). These influences are generally thought to be related to the square root of the tex value, so the exponent was expected to be -0.5. However, there is also expected to be an influence of the fibre fineness which may partly explain why -0.5 turned out not to give the best fit. It is the Fc and Fw coefficients that are used by the calibration routines in STARFISH to tailor the output of the model for a given set of processing conditions. This fact can be exploited, without need for the Starfish software. For example, any manufacturing company is in possession of large amounts of routine quality control data. These data are often just filed away and forgotten, but they can be used to form simple predictive equations that can be used during product development. This is done by, effectively, discovering the Ic and Iw values for the particular circumstances. The current values of all of these equation coefficients are given in the Program Code Segments given below. Back to TopSoftware Introduction & Overview

On the Starfish Install CD there is a set of PowerPoint presentations which give a brief introduction to the Starfish Research Project and the Starfish Technology. These presentations could be very useful to anyone who wishes to construct a modern piece of software in as much as they give a good representation of the on-screen appearance of the software, thus indicating all of the information that has to be presented to the user. The three that refer to the software are available here. Obviously, Microsoft’s PowerPoint Viewer will have to be downloaded to be able to run the presentations. 1 . Introduction 2 . Get Started 3 . Special Features In addition, scattered about the Program Help are bits of descriptive text which illustrate how Starfish is constructed and how it operates. These have been collected into seven documents, which are given here. 1 . Basic Technological Concepts 2 . Fabric Types 3 . Fabric Properties 4 . Knitting Parameters 5 . Knitting Production Parameters 6 . Wet Processing Parameters 7 . Definition of a STARFISH modelProgram Code Segments

These program snippets are lifted from STARFISH Version 6.5. Among the Research Records , you can find descriptions of earlier versions of the program, which may give some insight into the way that STARFISH evolved: from a calculation aid, to an in-house prediction utility, to a piece of commercial software. 1 . The STARFISH Engine 2 . Initialisation of variables - Including Reference State Equation Coefficients 3 . Comments - contents of major variables Back to Top .